There are various techniques available for repair and rehabilitation of concrete structure for failure and defects in concrete. These techniques and materials for repair of concrete is described.

Concrete is the most widely used and versatile construction material possessing several advantages over steel and other construction materials. However very often one come across with some defects in concrete. The defects may manifest themselves in the form of cracks, spalling of concrete, exposure of reinforcement, excessive deflections or other signs of distress.

On many occasions, corrosion of reinforcement may trigger off cracking and spalling of concrete, coupled with deterioration in the strength of the structure. Such situations call for repairs of affected zones and sometimes for the replacement of the entire structure.

Causes for Failures or Defects in Concrete Structures

The following are the major causes for failures of concrete structures:

- Structural deficiency arising out of faulty design and detailing as well as wrong assumptions in the loading criteria.

- Structural deficiency due to defects in construction, use of inferior and substandard materials, poor workmanship, and negligence in quality control and supervision.

- Damages caused due to fire, floods, earthquakes, etc.

- Chemical deterioration and marine environments.

- Damages caused due to abrasion, wear and tear, impact, dampness etc.

- Movement of concrete caused due to settlement of foundation, thermal expansion etc.

Identification of Failures and Defects in Concrete Structures

A correct diagnosis establishing the cause, nature and extent of damage, and the weakness or deterioration caused in the structure is very essential, since a faulty diagnosis may lead to improper selection of materials and repair techniques leading to the failure of the repaired zone again. It may also be necessary that the serviceability of the structure is checked after carrying out the necessary repairs.

Need for Repair and Rehabilitation of Concrete Structure

The need of structural repairs can arise from any of the following:

- Faulty design of the structure

- Improper execution and bad workmanship

- Extreme weathering and environmental conditions

- High degree of chemical attack

- Ageing of the structure

Techniques for Repairs and Rehabilitation of Concrete Structure

The technique to be adopted for repair or restoration of the structure depends on the cause, extent and nature of damage, the function and importance of the structure, availability of suitable materials and facilities for carrying out repair, and a thorough knowledge of the long-term behavior of the materials used for the repair work.

Depending upon the requirement, the repairing technique may be of a superficial (cosmetic) nature or, in some cases, may involve the replacement of part or whole of the structure.

The repairing techniques can be classified into three major groups:

- Injection into cracks, voids or honey-combed areas.

- Surface treatment

- Removal and replacing of defective or damaged material / area.

A variety of new materials have been developed for the repair and restoration of damaged structures by following any one of the above methods. These are briefly described below.

Materials for Repairs and Rehabilitation of Concrete Structure

Cement, Cement Grouts, etc.

In most cases, the repair material may be cement-based, since cement is the only active ingredient in concrete. Dry pack consisting of rich cement concrete or cement grouting may be suitable for sealing damaged areas and cracked portions.

Spraying of concrete or cement sand grout by means of high pressure nozzles, usually termed as ‘shotcrete’ or ‘guiniting’, respectively, may prove effective in many cases where a large surface area is to be repaired. The guiniting or shotcrete may be carried out with or without the use of steel reinforcing mesh or steel fibers.

Resin based Repairs of Concrete

The resins normally used are from epoxide, polyester, acrylic or polythene families. The application of resins for repair work requires a thorough understanding of their chemical and physical properties and their performance in the structure, particularly with the passage of time and under unfriendly environs.

Epoxy resin systems find application in civil engineering works such as grouting of cracks, repairs of eroded concrete structures, emergency repairs of bridges, aqueducts, chemically corroded columns and beams.

Generally, resin materials are used in repair and restoration work where properties such as, high strength (hence thin sections), excellent adhesion (hence small patches), quicker curing (hence saving in time), and high chemical resistance are required. One of the most commonly adopted resins is from epoxide. A brief description of the properties and applications of epoxy based resins is given below.

Epoxy Resins for Concrete Repair

The resin mortar may be obtained by adding fillers such as coarse sand or calcined bauxite grit. The chemical reaction begins as soon as the resin and hardener are combined. Most combinations have a pot-life between 30 and 60 minutes. They develop excellent strength and adhesive properties and are resistant to many chemicals besides possessing good water proofing.

Epoxy resin when cured with different hardeners offer wide range of properties. Once cured, they form irreversible system (thermosetting).

The characteristic properties of cured epoxy resin systems repair and rehabilitation of concrete structure are

- High adhesive strength to almost all materials

- Low shrinkage during curing

- Exceptional dimensional stability

- Natural gap filling properties

- Thermosetting (does not melt)

- Resistance to most chemicals and environments

- Ability to cure in wet conditions and underwater (for selected grades)

- Ease of application

Procedure of epoxy resin grouting

- Locating the cracks

- Cleaning of the cracked surface

- Drilling and fixing of nozzles for grouting at suitable intervals with epoxy putty

- Grouting of epoxy mixture with the help of the grout pump

- Sealing of nozzles through which grouting is done

A grout vessel essentially consists of a pressure vessel (to withstand 10 – 15 kg/cm2pressure) with inlet and outlet for resin mixture, pressure gauge, connection for compressed air with regulator for pressure grouting.

A pre-mixed resin + hardener is filled in the grouting vessel and through the nozzle the activated resin is pumped in the cracks. When cracks get filled in, the grouting is carried in the next nozzle and so on till all the cracks are filled in.

When cured, the epoxy resin improves the load carrying capacity of the cracked structure.

Bonding Old to New Concrete

Epoxy resin with a special polyamide hardener combination is successfully used for bonding old to new concrete.

The process consists of —

- Removal of all loose and damaged concrete using mechanical means or water jet

- Surface to be dried

- A suitable epoxy resin [unmodified solvent less epoxy resin + polyamide hardener (special grade)] is applied with stiff nylon brush

- The fresh concrete should be poured when epoxy coating has become just tack free

- Care should be taken not to completely dry the coating.

Epoxy resins are a not primary construction material. A judicious use of these resins is required in view of the high cost of these resins. The resins should be used in emergencies.

Properties of epoxy resin systems can be advantageously exploited, when other materials cannot be used due to strength or other considerations. Epoxy resins are finding many new applications in pressing conditions such as underwater repairs of dams, ships, etc. Many new applications will be found using epoxy and other synthetic resins in future.

Polymer Concrete Composites

Most of the deficiencies found in ordinary structural concrete are removed using polymer concrete composites either in the form of a surface coating over the structure or by impregnating it into the structure.

Polymer concrete composites are relatively new developments and have been used in structural applications since 1950. They possess very high strengths and are more durable and resistant to most chemicals and acids.

There are three types of polymer concrete composites, namely polymer impregnated concretes (PIC), polymer concretes (PC), and polymer cement concretes or polymer modified concretes (PCC or PMC). In PICs the monomers (usually styrene, methyl-methacrylate (MMA), polymethyl methacrylate (PMMA), etc.) are impregnated into the pore system of the hardened concrete, thereby filling up the pores and making them impermeable and resistant to chemical attack; In PCs the polymer is the sole binder in lieu of cement and water. In PCCs and PMC s, a polymeric additive (latex or pre-polymer) is added to the normal cement composite during the mixing stage itself.

All the three types of polymer concrete composites are useful for carrying out repairs and restoration work in damaged structures. The use of these composites for post-distress and post-failure applications is steadily increasing because of their superior durability, excellent bond to parent concrete structure, superior abrasion and wear-resistant properties, a high degree of resistance to chemicals like chlorides and acids, and their very low water absorption. Repairs of cracks can be easily carried out by injecting the polymer concrete damaged by corrosion of reinforcement can be chipped off and replaced by polymer concrete.

Sealants

Many commercial sealants are available for sealing of cracks in concrete structures. Joint sealants should ensure structural integrity and serviceability. They should also serve as protection against the passage of harmful liquids, gases, and other undesirable substance which would impair the quality of concrete. In the case of repair of a cracked surface, the cracks are first enlarged along their exposed face and are pointed up with the sealants.

Surface Treatment to Concrete

The durability of the concrete can also be increased particularly on the surface by applications of different materials which make it waterproof, hardened and resistant to chemical attack.

Some of the commonly used surface treatments are:

- Sodium silicate, magnesium or zinc fluoride

- Drying oils like Tung or Linseed oil

- Chlorinated rubber paints and neoprene paints

- Epoxy paints

- Silican Fluoride treatment

The surface of the hardened and dry concrete can be made abrasion resistant and less dust generating by application of solutions of sodium silicate, magnesium or zinc sulphates or silico fluorides. Drying oil like tung oil or linseed oil can be used. Alternatively, carborundum or fused alumina or finely divided iron aluminum chloride preparations may be added in the surface layer while placing the fresh concrete.

Floor paints also provide reasonable durability if the traffic on floor is not heavy. Paints containing synthetic resins particularly polyurethanes or epoxies or chlorinated rubber provide greater resistance to wear. They also protect against solutions of salts and dilute acids.

Sodium silicate and silico fluoride applications provide protection against mild conditions of attack by aqueous solutions or organic liquids. Bitumen and coal tar gives protection against insects and borers. Some plastic materials, rubber latex glass fiber coatings and PVC linings have also been successfully employed to improve durability of concrete.

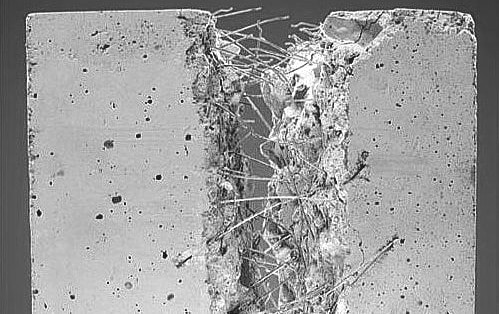

Steel Fiber Reinforced Concrete

Use of small diameter steel fibers in concrete has been found to improve several properties of concrete and particularly its tensile strength and impact and wear resistance. One of the uses of steel fiber reinforced concrete (SFRC) is in the area of repairs and restoration of concrete structures.

The damaged portions of a concrete structure can be removed and can be made good by placing of SFRC to the sides and bottom of damaged structures by guiniting or shotcrete techniques. Because of its improved wear and tear and abrasion resistance, SFRC has been successfully employed for the repair of industrial floors and bridge decks with or without the use of polymer concrete.

Other Materials for Repair and Rehabilitation of Concrete

There are several other materials which can also be used for repairs of certain structures. For repairs to existing foundations, special chemical grouts have been developed which will ensure the compaction of the soil below and provides protection to the reinforcing steel in the foundations. Superplastized fiber reinforced concrete has been used in carrying out repairs to machine foundations and underground structures.

Certain chemicals and surface coatings marketed under brand names are said to seal the cracks in structures like water tanks and afford sufficient protection to the steel from corrosion. Special paints (latex or bitumen based) have also been developed for applying to the concrete surface or to the bars for making them resistant to aggressive environs.

With the increasing number of cases of damages being observed on structures built in the past, repairs and rehabilitation of such structures have assumed greater importance. Some of the techniques and materials found useful to reinstate some affected structures.

Table below shows the materials generally recommended for repair of concrete structures. Epoxy resins and concrete composites show high potential as promising repair materials.

Timely detection of deficiencies in concrete and steel of an existing structure and execution of immediate remedial measures will prevent further deterioration of the structure and will result in huge savings in the maintenance cost.

The old dictum, ‘prevention is better than cure’ is applicable to concrete structures, both at the time of constructing the structures and at a time when the structure has shown signs of initial distress.

Materials for Repair of Concrete

Repair

Operation

|

Material

|

Comments

|

Sealing of fine cracks

|

- Epoxy resins

|

– Good bonding properties even in the

presence of moisture

|

Sealing of large cracks and joints

|

- Portland cement Mortar

- Polymer mortar

- Putties and caulks

|

– Well – compacted

– Good bonding properties

– Based on synthetic polymers and

tars

|

General sealing of surface

|

- Synthetic polymers and asphalt coatings

|

|

Localized patching of surfaces

|

– Concrete or mortar using Portland

cement

– Rapid-setting cements

– Polymer resins; epoxies;

polyesters

|

– Calcium aluminate and regulated-set

cements

– Good bonding

|

Overlays and shotcrete

|

– Portland cement concrete

– Steel fiber reinforced concrete

– Latex modified concrete

– Polymer concrete

– Asphaltic concrete

|

–Quick-setting admixtures

– Resistance to cracking

– Good bonding

|